Our Services

Trenchless solutions for a cleaner, more sustainable future. We specialise in UV-cured CIPP technology to renew pipelines without the mess and disruption of excavation. Our methods minimise waste, reduce carbon emissions, and extend the life of vital infrastructure — delivering stronger, longer-lasting results while protecting the environment and the communities we serve.

Pipeline Services

Cleaning, CCTV Inspection and Condition Assessment

Using our high-powered cleaning units to flush debris, remove foreign objects and roots from the pipelines with a closed-circuit television (CCTV) unit our inspection teams have the equipment to perform a thorough pipe inspection. The CCTV inspection teams are equipped with advanced inspection systems capable of working in various size pipes ranging in diameter from 50mm and 1,600mm to produce top quality images. Our coloured pan and tilt crawler mounted cameras supplied by leading international manufacturers have the capability of measuring pipe diameter, ovality and grade.

Once the inspection is completed our technical staff assess the CCTV footage using two software’s being Cleanflow & Wincam to generate an inspection report that is compatible with the latest NZ Pipe Inspection manual. Once the condition assessment is complete our technical staff identify the appropriate pipeline repair method.

Trenchless Renewal of Deteriorated or Damaged Pipes

Depending on specific factors related to site conditions, environmental considerations, effluent composition, and temperature, we select the most suitable lining materials and curing methods from the wide variety in our arsenal. Our experienced teams are equipped with the resources to safely carry out all the auxiliary activities related to lining such as pre lining preparation, source detection and CCTV inspections in addition to post lining reopening of live later connections, installing Lateral Junction Repairs (LJRs), testing and final CCTV inspections. Trenchless manhole rehabilitation is another field where we provide our services in, as part of the network renewal process.

We are currently working with our international partners on utilising our experience and resources to expand into the lining of pressure pipelines in the fields of water supply and wastewater. This field is not new to several of our senior staff as they have successfully delivered similar products in the past.

Lateral Lining

Lateral Lining

Rehabilitation & Repair

Cured in Place Pipe Lining (CIPP)

The CIPP liner is designed according to the following factors:

+ Pipe condition, depth & ovality

+ Pipe Loading including traffic loading, hydrostatic loading

+ Chemical composition, and temperature of effluent, surrounding soil

Our key staff technical and field expertise and wide range of resources and equipment allow us to successfully tackle complicated and challenging projects on pipes ranging in diameter between 100mm to 1,500mm.

Factors taken into consideration when designing the liner and selecting the appropriate products and method include pipe condition, ovality, traffic and other live loading, pipe depth, water table level, chemical composition, and temperature of effluent, surrounding soil, site environmental sensitivity and impact on residents and public in the project area. Our key staff technical and field expertise and wide range of resources and equipment allow us to successfully tackle complicated and challenging projects on pipes ranging in diameter between 100mm to 1,500mm.Lateral Junction Repairs

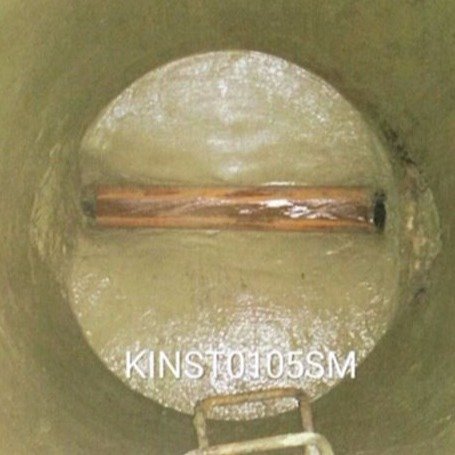

The process involves installing a resin impregnated branched patch that is cured in place by ambient cure/heat or UV curing. The lateral junction repair (LJR) is compliant with the international standard ASTMF2561- 11. NZ Lining have the expertise and resources of serval LJR We have the capacity to install LJRs on pipe mains ranging in diameter between 150mm to 900mm.

The same trenchless process of Lateral Junction Repair is also used to seal the junction between a lateral pipe and a newly CIPP lined main to prevent water or roots coming through the lateral from going between the pipe and liner. NZ Lining have the expertise and resources of several LJR systems utilising ambient cure, heat cure and Ultraviolet cure lining techniques. We have the capacity to install LJRs on pipe mains ranging in diameter between 150mm to 900mm.

Lateral Lining

Our lateral lining service is compliant with the international standard ASTM F1216-16.

Manhole Rehabilitation

Depending on the existing substrate NZ Lining offer three different coating systems being:

+ Cementitious Coating

+ Epoxy Coating

+ Complete Manhole Lining

Our full service brochures

To read more about our services & processes, download our full service brochures below.